Quality Control

Powered by AI Image Processing

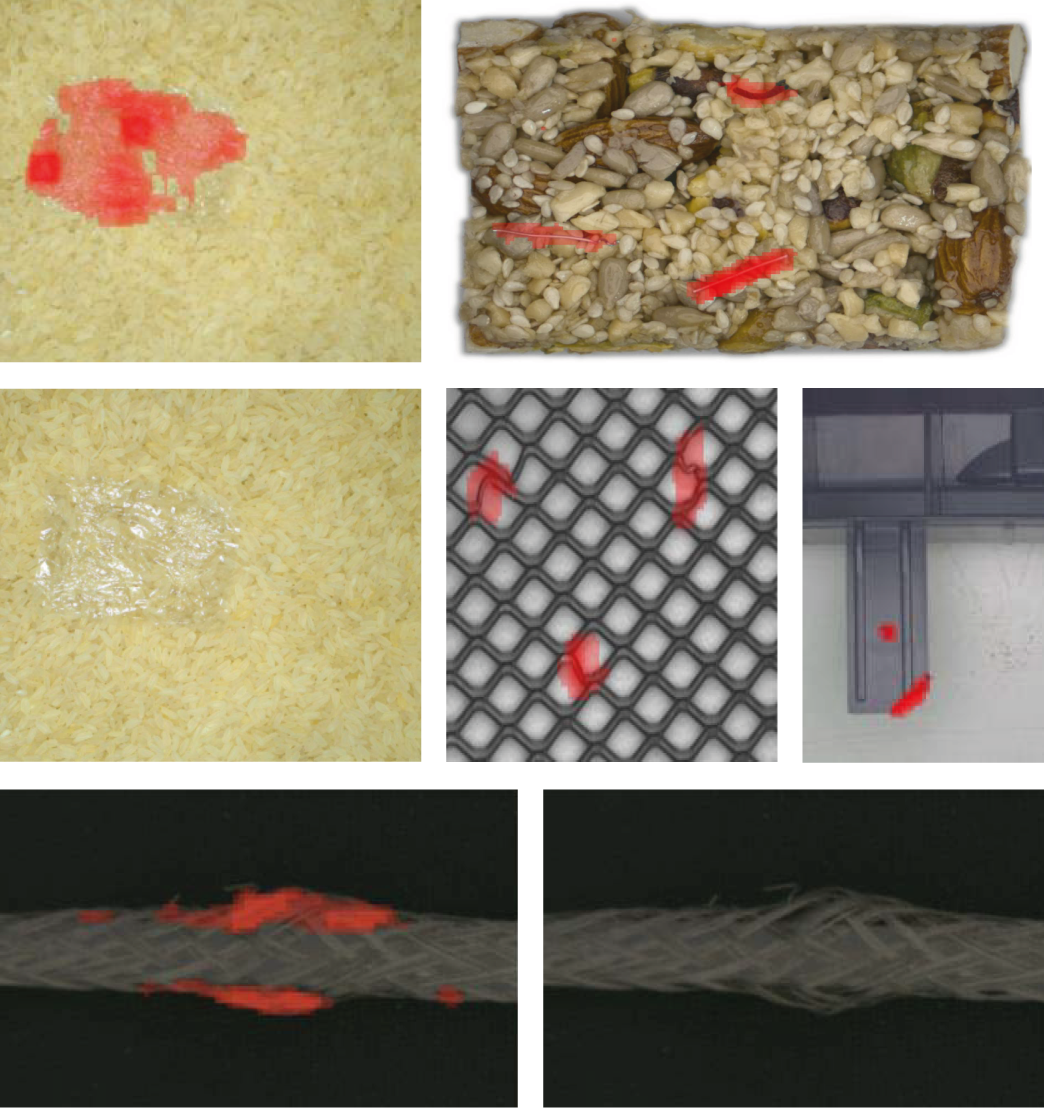

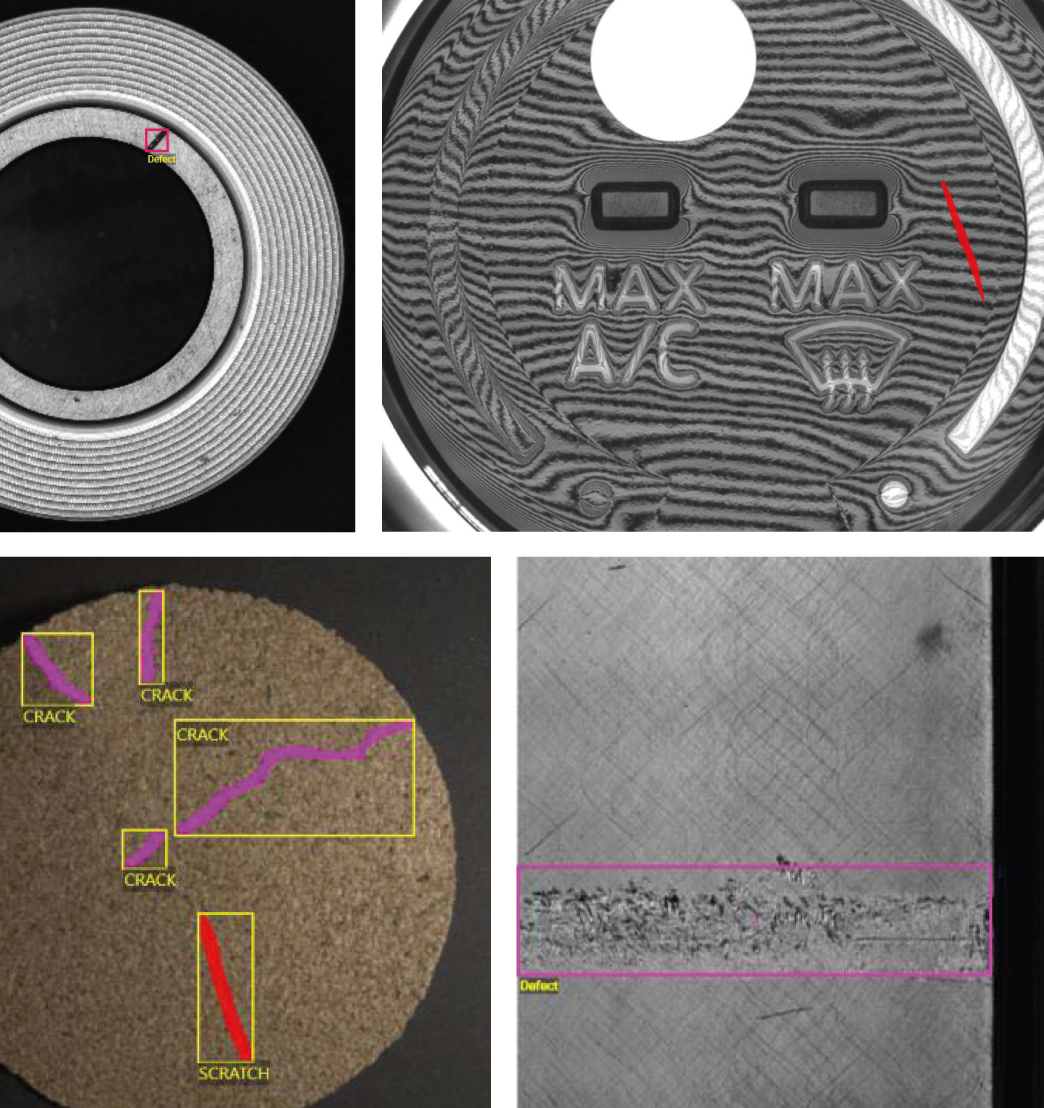

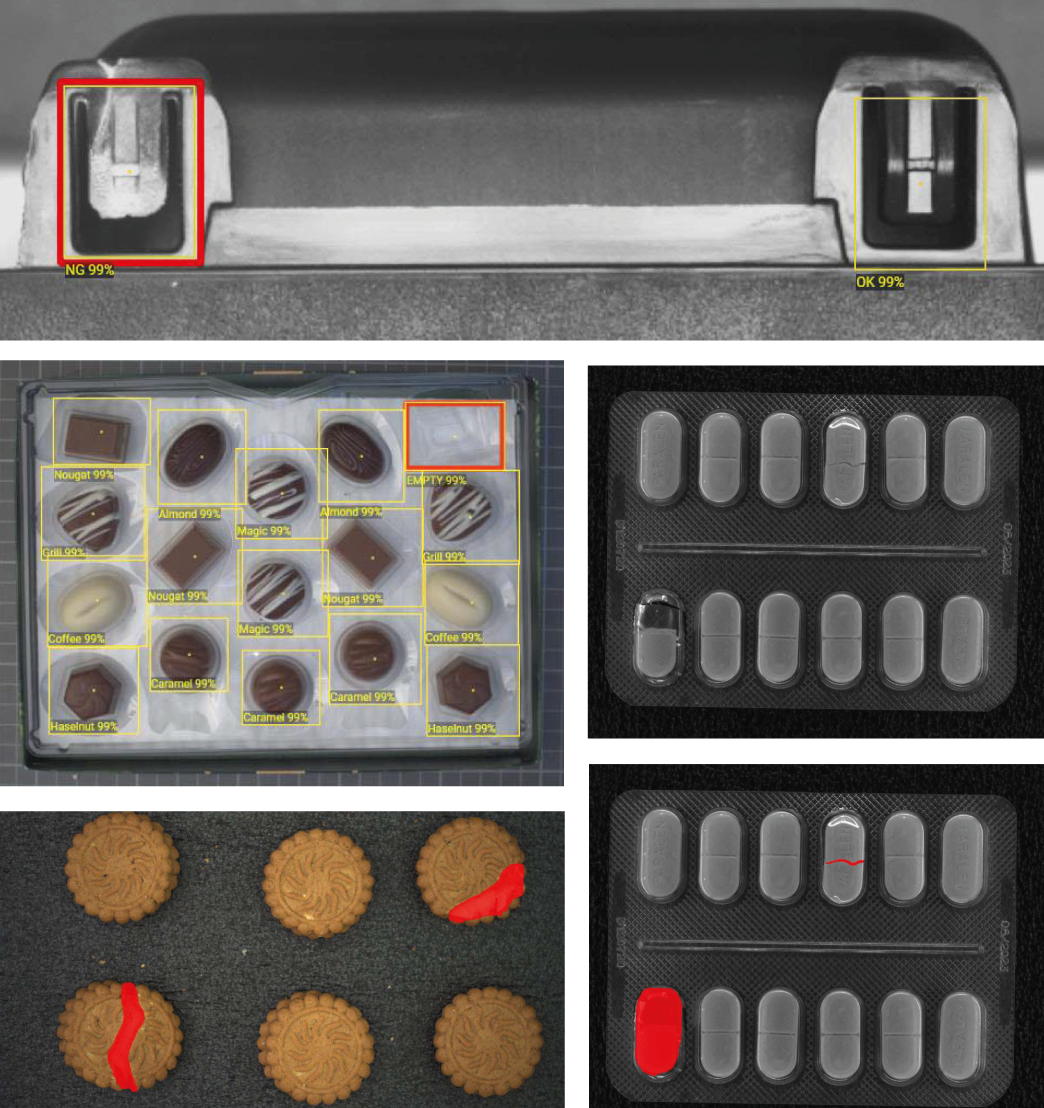

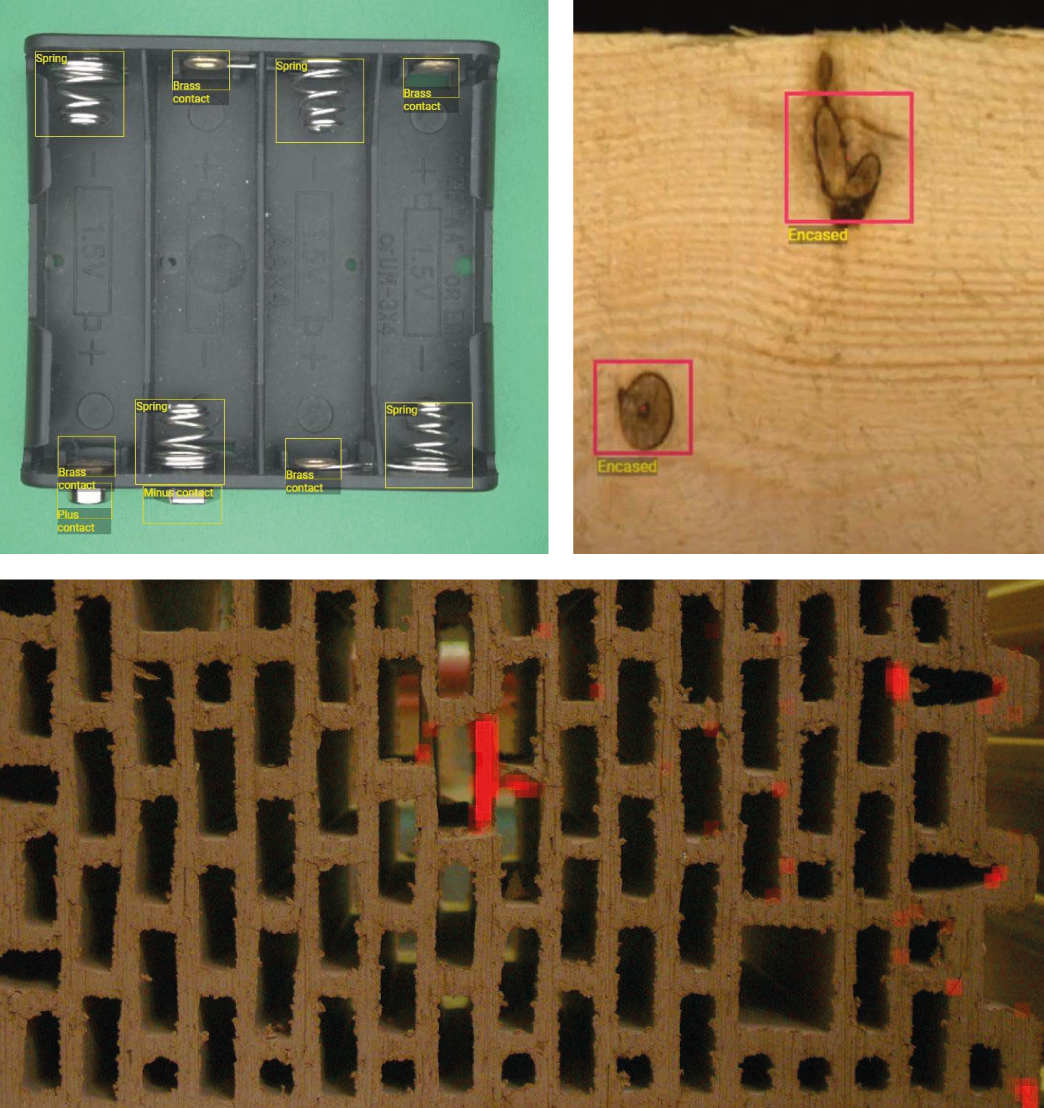

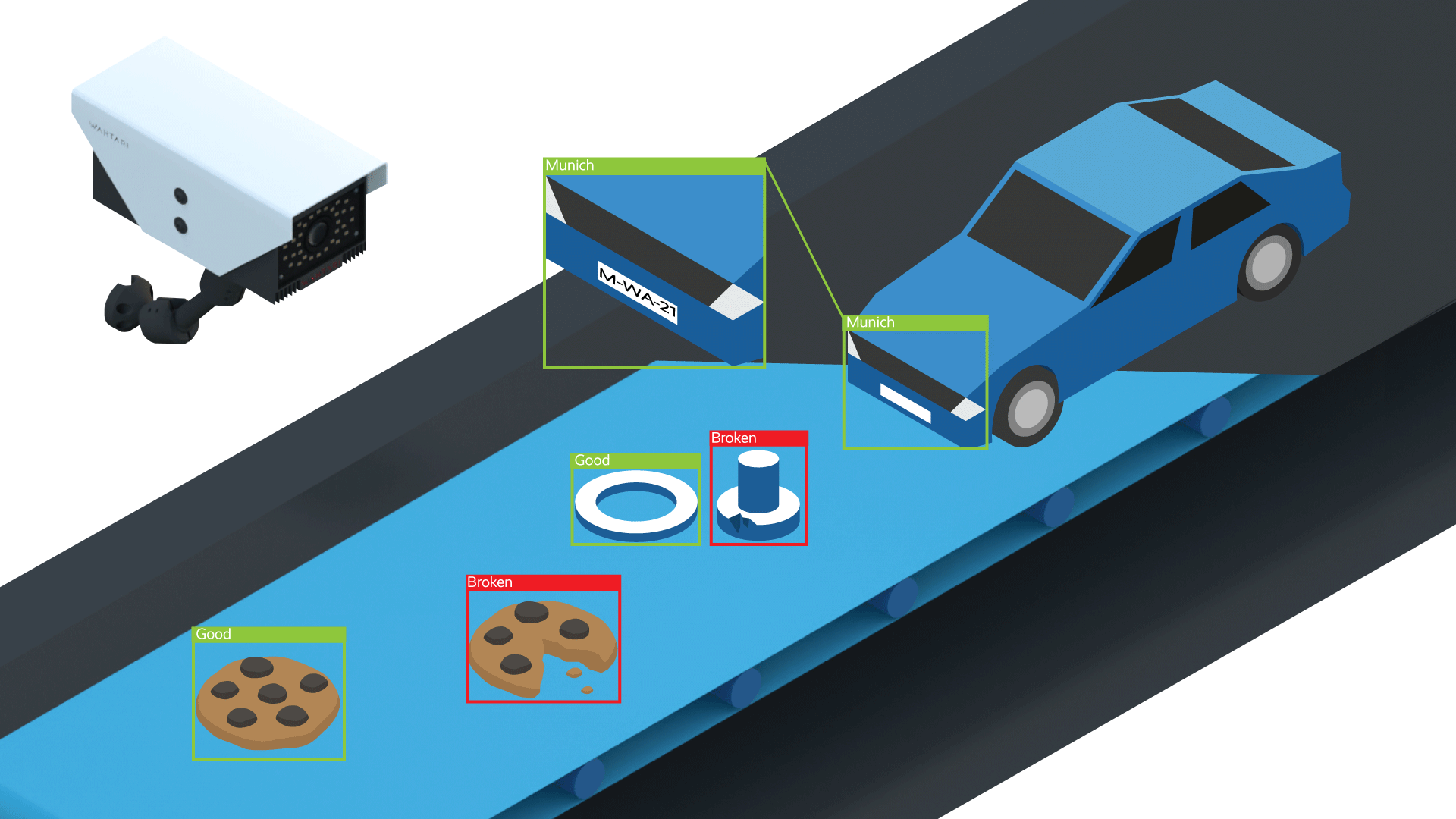

An AI-based inspection system can reliably detect complex situations and geometries regardless of the number, size, shape, material and position of the components – even under difficult viewing angles & lighting situations.

Use Cases

End-To-End Solution from a single source

LPR/ Anpr | Personal Protective Equipment | Inspection of FFP2 Face Masks | Bark Inspection of Tree Logs | Inspection of Conveyor Belts | Inspection of Roof Tiles

Modern AI systems form an essential basis for the automation of visual quality control.

Deep neural networks can be trained to recognize complex patterns and microscopic material defects in order to identify and isolate damaged products.

The knowledge gained from the analysis of product quality can also be used to draw conclusions about the current state of production machines and processes. Artificial intelligence therefore not only ensures the high quality of your products but also that wear and tear and malfunctions of the machines are detected during operation. In this way, it is possible to react in real time to quality losses in order to minimize breakdowns and rejects.

In order to utilize the full potential of AI technology and to be able to react immediately to the collected data, real-time data processing on AI hardware is useful. Wahtari offers 100% AI edge solutions, so that your data does not leave your company network.

Automatic quality control simply explained

Areas of Application

Artificial intelligence as a tool for

Quality Control

Defect Detection

Even very similar objects are clearly

distinguished.

Object Detection

Even very similar objects are clearly

distinguished.

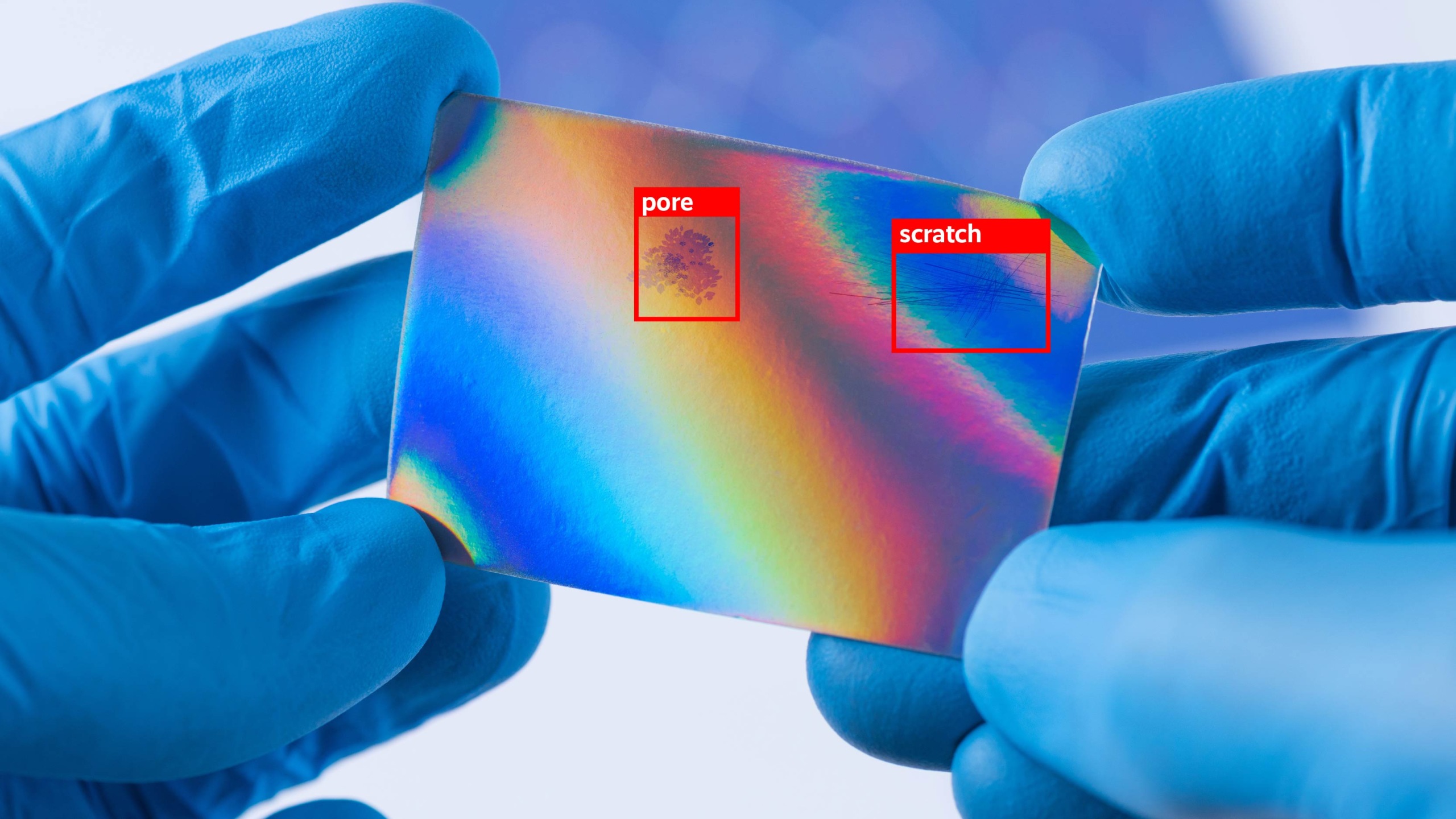

Surface Inspection

E.g. pores, inclusions, scratches, paint runners, orange peel skin.

Color Detection

E.g. color values, color gradients, discolorations, minimal deviations from the target value.

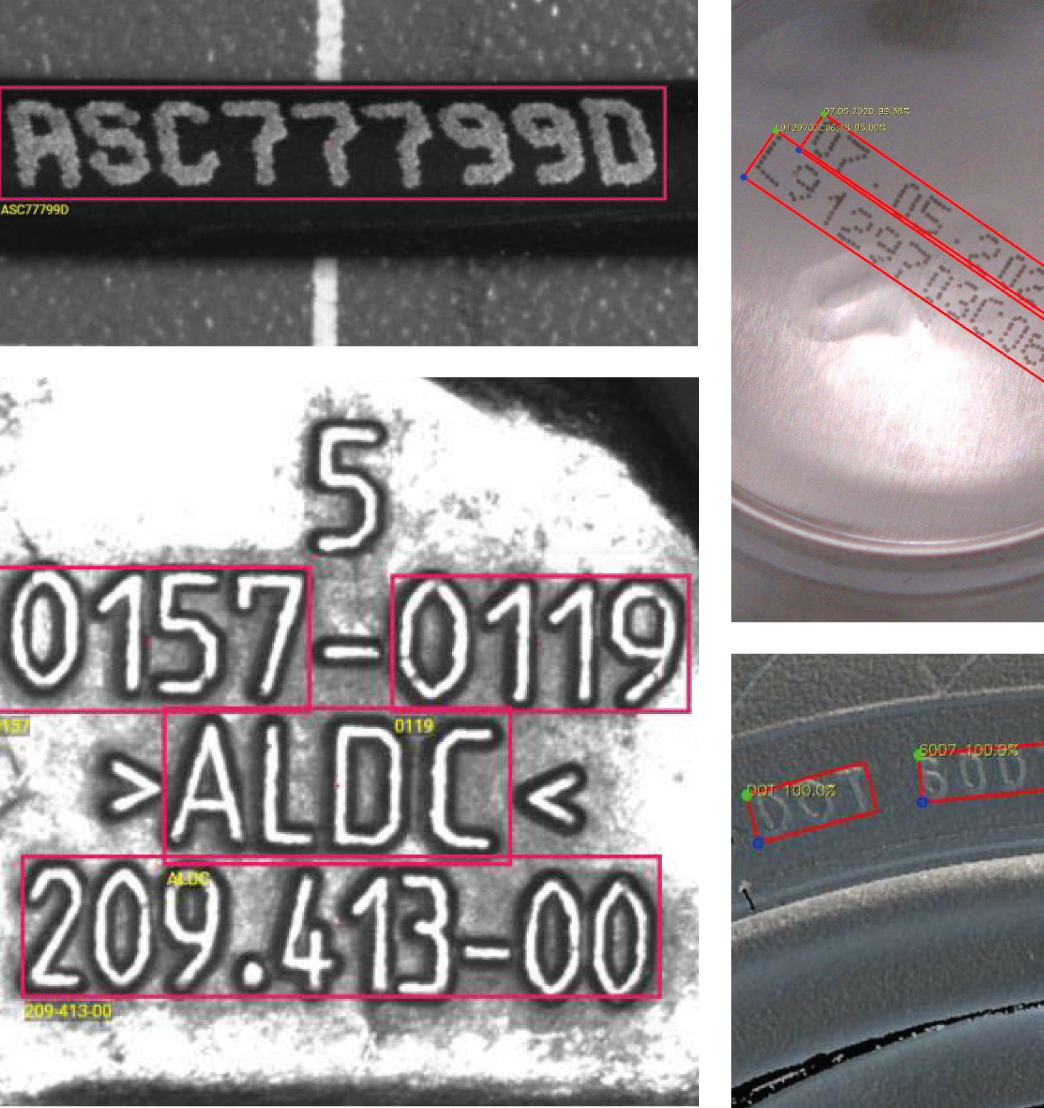

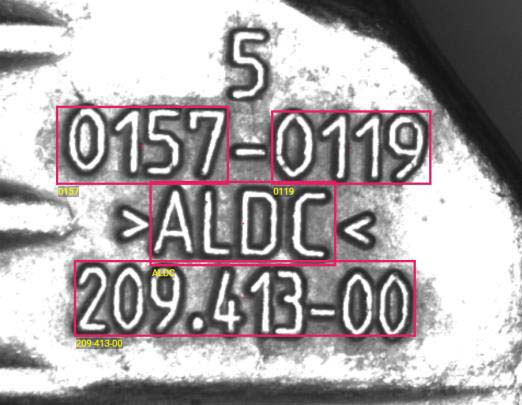

Text Recognition

Independent of language & font.

E.g labels, engravings, product marking.

Completeness Check

E.g. missing, surplus, wrong components or objects.

Advantages of Wahtari AI systems

AI Model | AI Software | AI hardware

Complex Tasks

We solve tasks that cannot be managed in simple ways.

High precision

Even minimal production errors are reliably detected.

Extreme performant

Detection of production errors in realtime.

Easy adaptation

Hassle-free training of new products & criteria.

Conserve resources

Fewer rejects through precise localization and identification of the defect.

Seamless integration

Easy integration with third-party applications & industry interfaces.