nSpect PCB Inspection

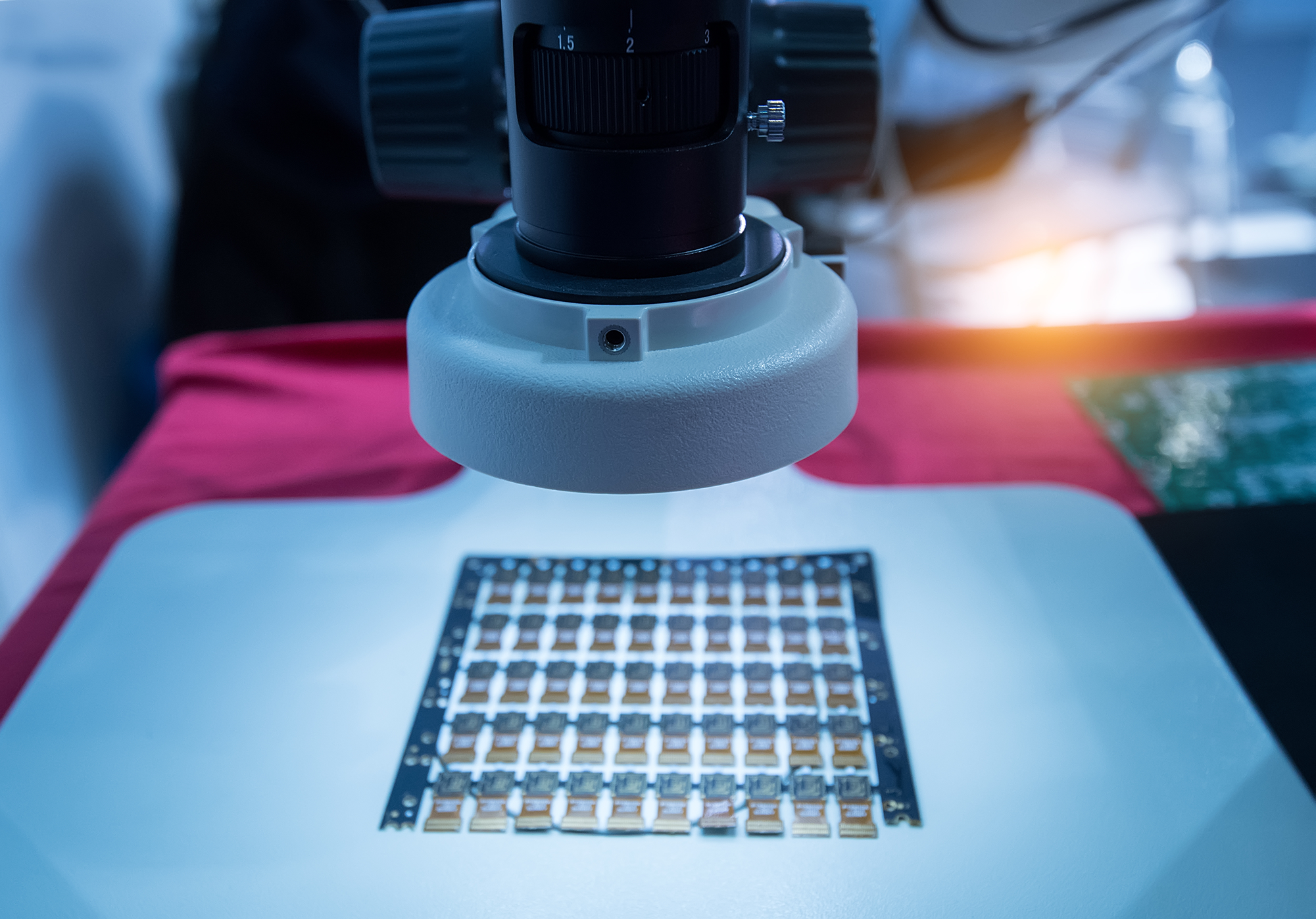

Wahtari’s nSpect PCB inspection solutions can analyse a wide variety of product and quality characteristics in individual inspection (test bench) or Inline during ongoing production. Deviations are signaled and documented.

The systems are available in different versions and can be adapted to a wide range of requirements. The analysis & evaluation is performed on-the-edge, without connection to a cloud, for highest performance, lowest latencies and best data security.

The commissioning does not require any technical knowledge. Product features are simply trained according to the “Teach & Go” principle by using a master sample.

Key-Features

360° Analysis

Complete detection of the cable surface

Teach & Go

Few minutes to teach-in the product features according to a master sample

Vibration- insensitive

Vibrations of the floor or the cable are no problem

High performance

Up to 1500m/min cable speed

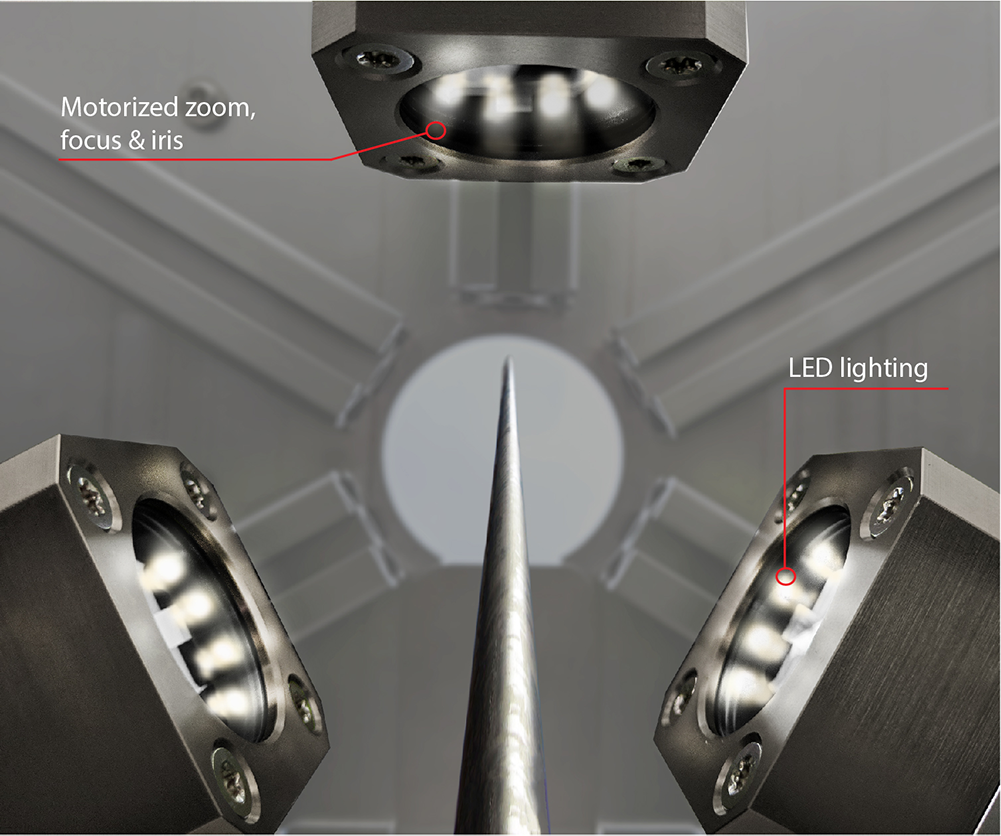

Adaptable LED lighting

Adjustable to many cable types

Dashboard

All data at a glance

Areas of application

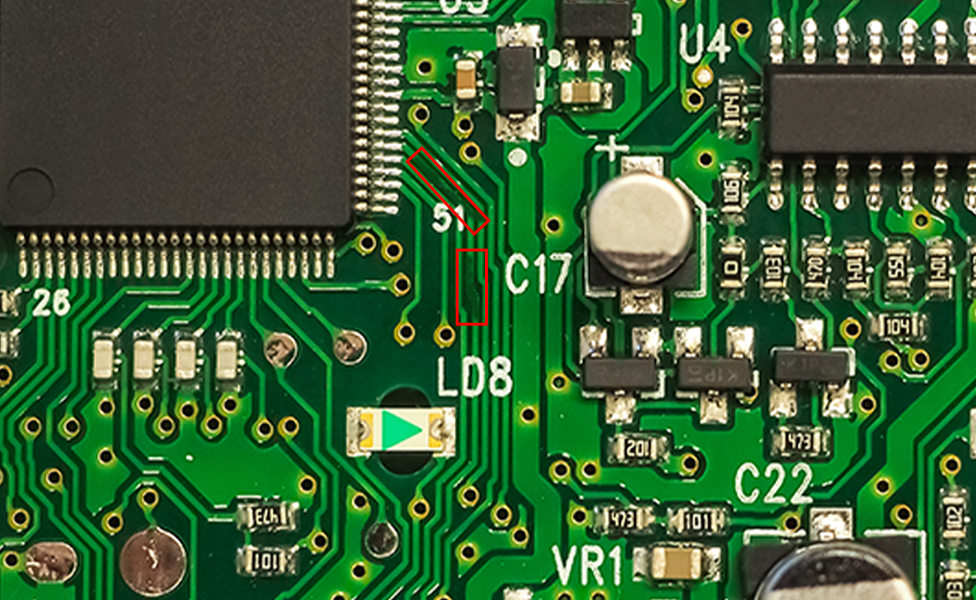

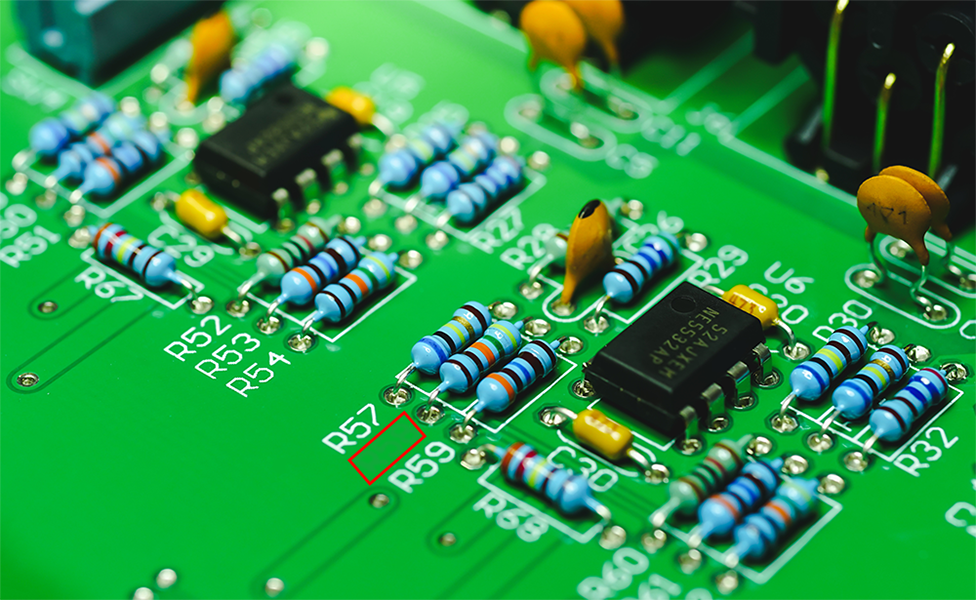

Artificial intelligence as a heart for automatic defect recognition on PCB boards

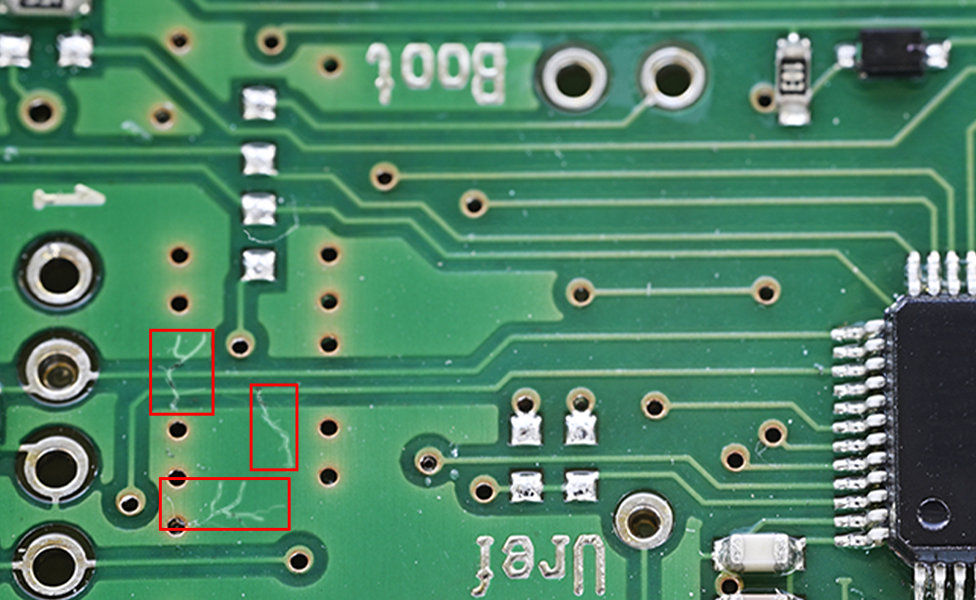

Surface examination

Breaks, cracks, cuts,

holes, dents, pimples

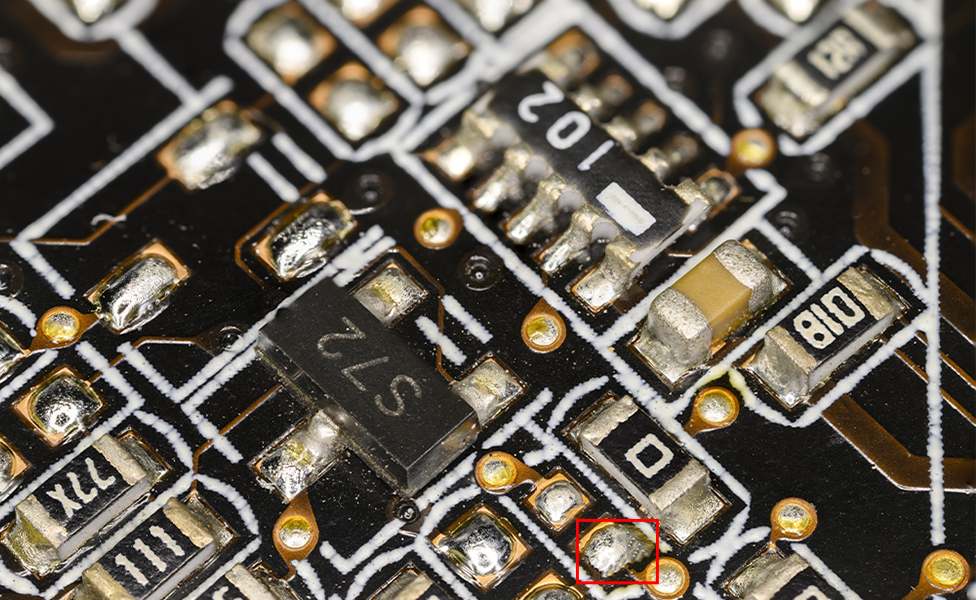

Solder joint quality

Monitor cold soldering joints

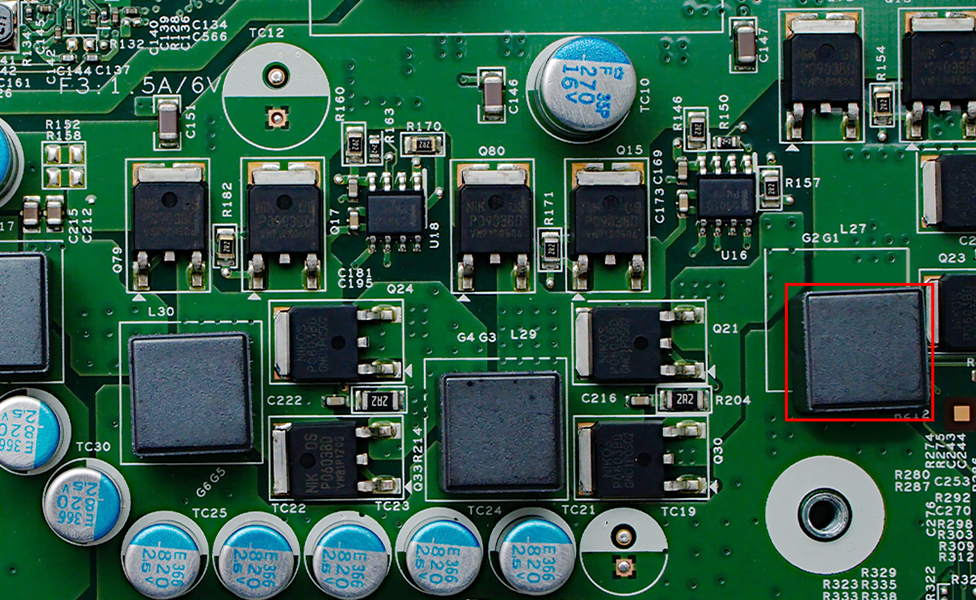

Position & presence control

Conductor tracks

Monitor broken conductor tracks

Check imprints

Markings, codes,

lettering, serial numbers

Key-features

Teach & Go

Few minutes to teach-in the product features according to a master sample

High performance

Adaptable LED lighting

Adjustable to fit board color

Continuous or Batch Analysis

Adaptable to your process

Dashboard

All data at a glance

Technical Highlights

Low maintenance

No tools necessary System signals when cleaning is necessary

Non-contact measurement

No damage or influence on the product

24 months manufacturer

warranty

10 years spare parts support

24/7 continuous operation

> 99.5% availability

Measuring range IP67 protected

Measurement of wet media / easy cleaning

Networkable

Recipes available remotely

Process reliable

Insensitive to water drops and dust particles on the cable surface

Low maintenance

No tools necessary System signals when cleaning is necessary

Non-contact measurement

No damage or influence on the product

Installation length

Max. 500mm incl. rack

Max. 250mm for fixed installation

Installation depth

Max. 500mm

Height adjustable

Cable passage height 800-1200mm

24 months manufacturer

warranty

10 years spare parts support

24/7 continuous operation

> 99.5% availability

Production spped

> 0-500m/min (all test types) up to 1500m/min (color analysis)

100% control

For highest quality requirements

Measuring range IP67 protected

Measurement of wet media / easy cleaning

Random rotating products

Insensitive to cable rotation

Networkable

Recipes available remotely

Process reliable

Insensitive to water drops and dust particles on the cable surface

Error length

Larger 0,3mm

Product diameter

0,5mm – 25mm round, oval and flat

Functionality of the nSpect PCB inspection solution

Problem

The increasing demands on the already high quality standards, e.g. as demanded by the automobile industry, pose problems for error detection by means of conventional measuring and testing technology. In addition, requirements such as 100% control and traceability have to be fulfilled.

nSpect PCB

The nSpectPCB inspection solution was developed specifically for the PCB production industry and enables the inspection of many di fferent product features in a single compact device. Thereby it replaces the existing measuring and testing technology, which reduces investment and maintenance costs as well as integration e fforts. A high-speed camera continuously monitors the complete surface of PCB products.