Conveyor Inspection

AI conveyor inspection with Wahtari nCam

Real time conveyor inspection with AI

Detecting wear and tear of conveyor systems with real time belt health status information allows you to schedule maintenance downtimes and avoid unforeseen interruptions during your valuable production time.

Open architecture for integrated solutions

Wahtari conveyor inspection provides an open interface with many industry standards like OPC UA, ProfiNet, ProfiBus, Ethernet and more, which gives you all degrees of freedom to create your own integrated solutions and adopt to existing systems.

Real time conveyor

inspection with AI

Detecting wear and tear of conveyor systems with real time belt health status information allows you to shedule maintenance downtimes and avoid unforseen interruptions during your valuable production time.

Open architecture for integrated solutions

Wahtari conveyor inspection provides an open interface with many industry standards like OPC UA, ProfiNet, ProfiBus, Ethernet and more, which gives you all degrees of freedom to create your own integrated solutions and adopt to existing systems.

Areas of Application

Artificial intelligence as a heart for automatic detect recognition on conveyor belts.

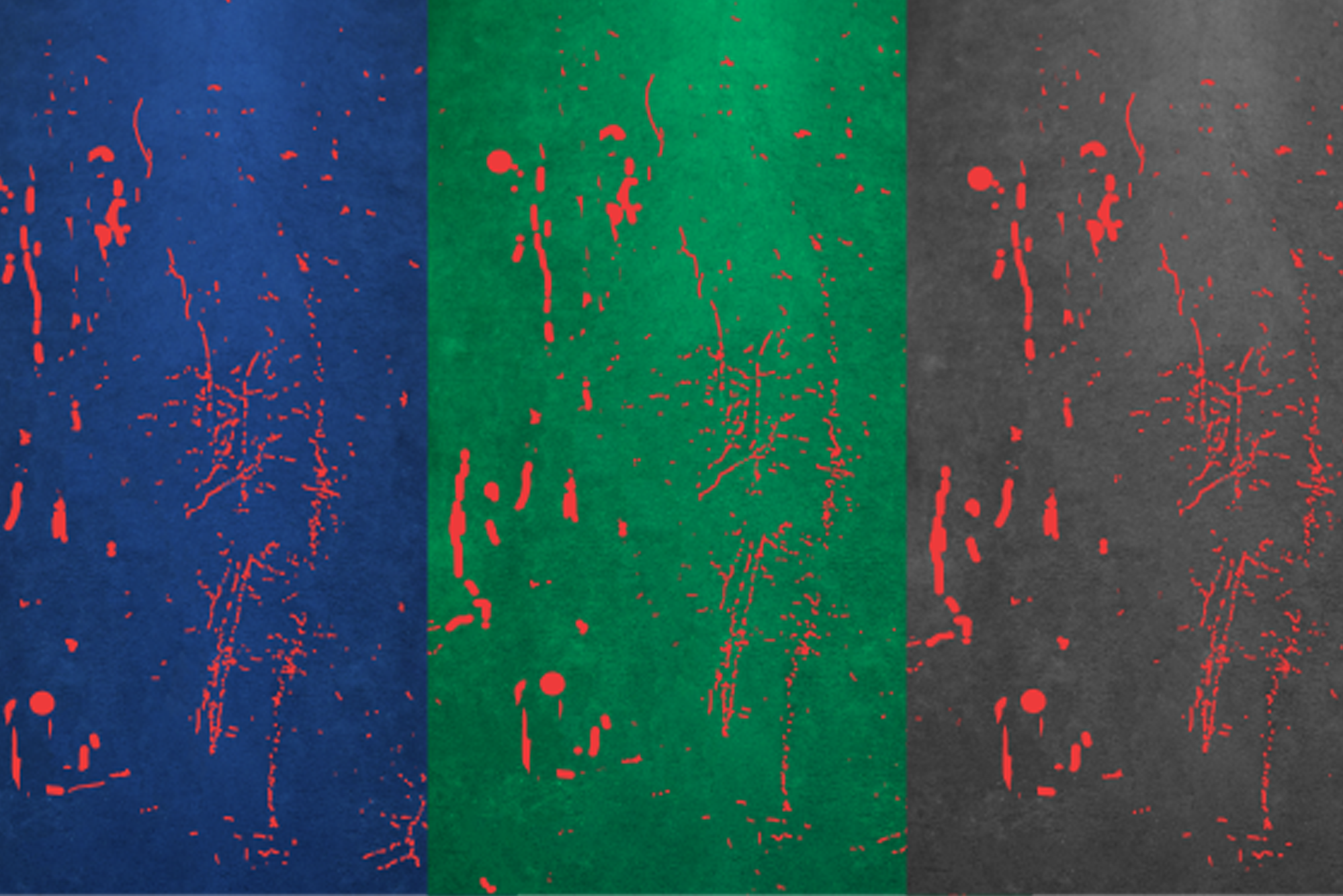

Surface Examination

Monitor wear & tear, cracks, cuts,

holes, shreds

Control Lap Joint

Monitor belt joints

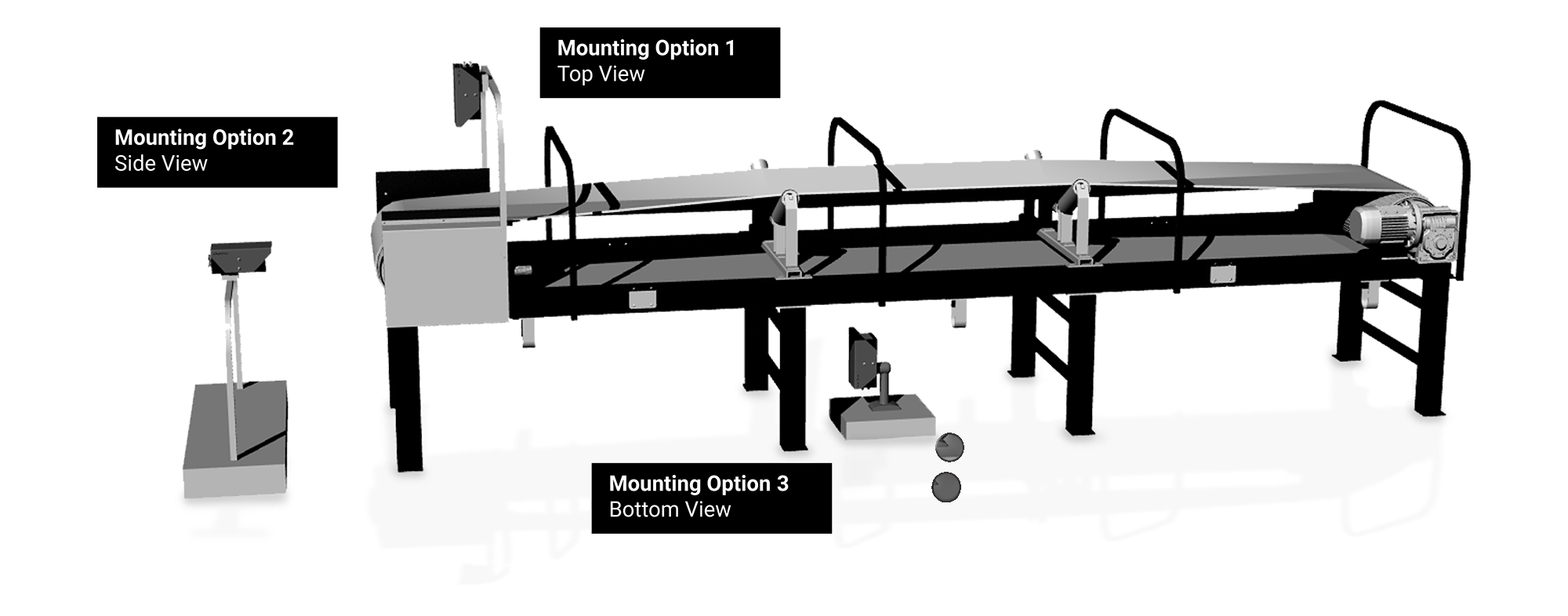

Flexible

Multiple mounting and

monitoring options

Highspeed

< 15m/s belt speed

Adaptive

Supports different belt types

Adjustable

Supports multiple belt colors

Technical Highlights

AI “On-The-Edge” Technology

Open architecture

easy to integrate into your system

Integrated lighting

Industrial connectors – M12

Modular design

Industrial housing

Motorized lens

Made in Germany

Fast installation

Plug & Play

High performance

with onboard processing based on Intel AI hardware

Conveyor Inspection in Your Company

Interested?

How to get your conveyor belt inspection :

1) Initialization meeting: Clarify the general conditions

2) Decide on a nSpect standard product or we create your individual solution