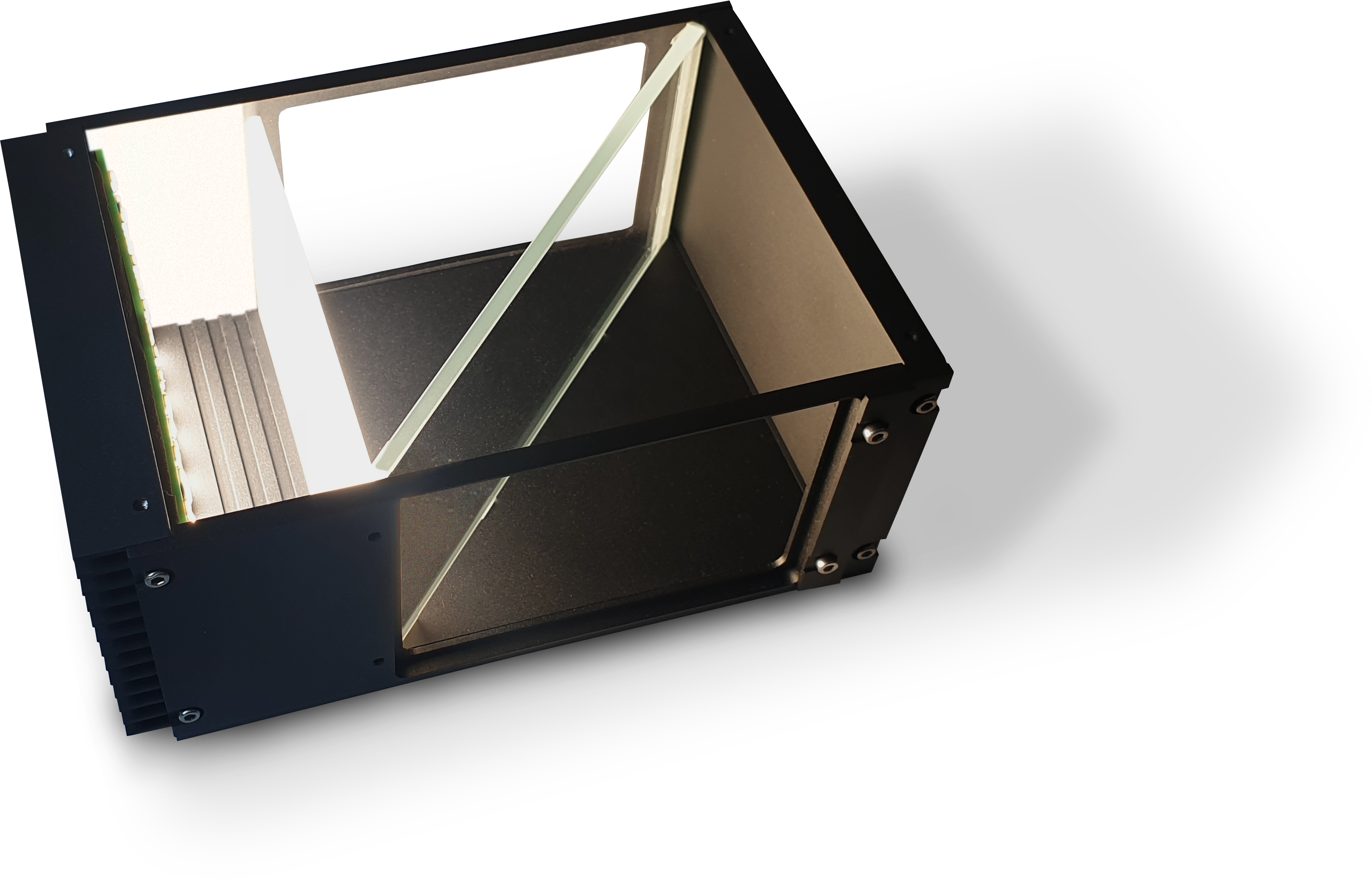

nLight coax

The highlight for Machine Vision

nlight coax – the coaxial light by Wahtari – ensures the best lighting conditions for machine vision applications

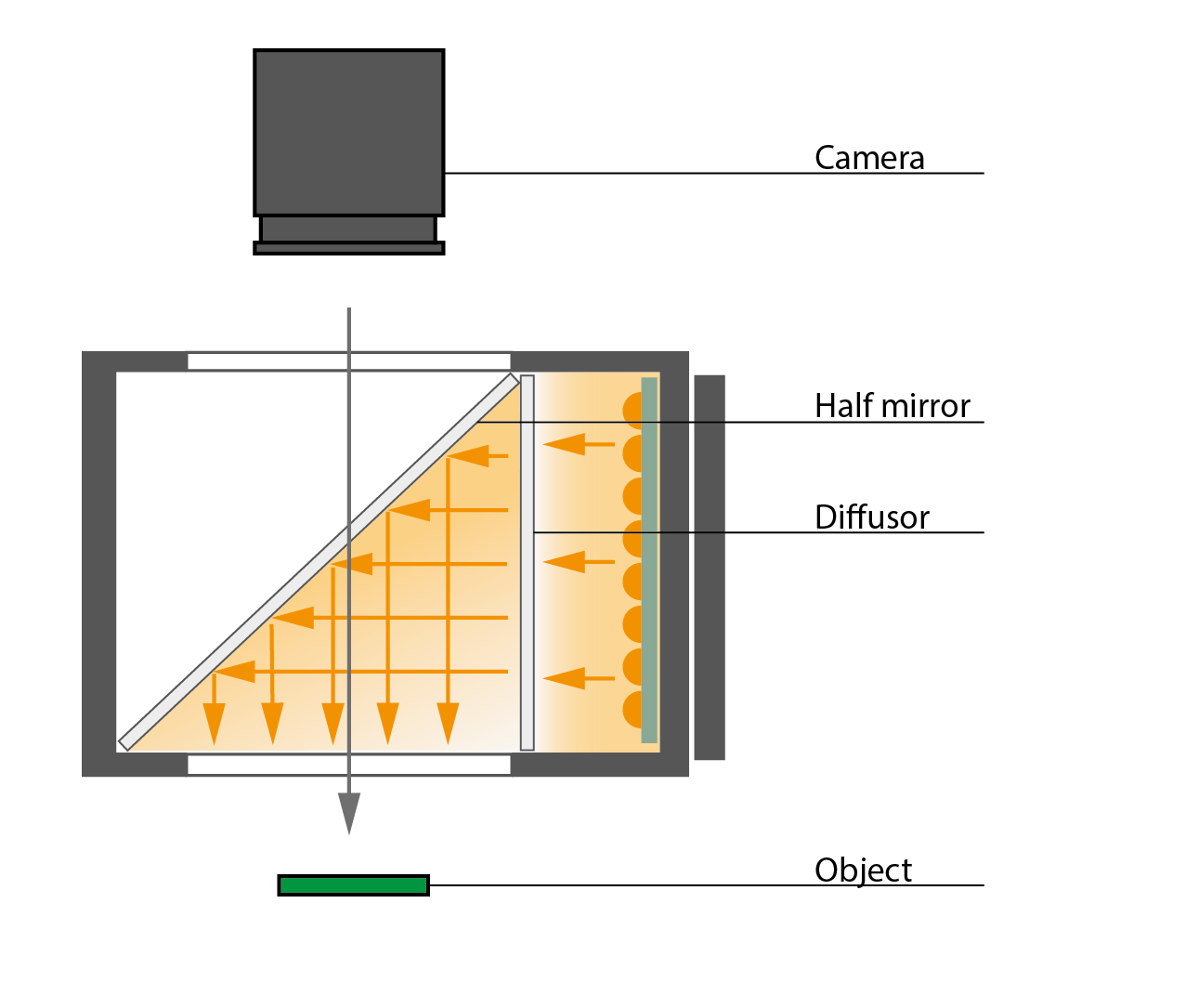

For coaxial illumination, the light source is not aimed directly at the object, but is parallel to it. A half- mirror at an angle of 45° to the light source directs the light rays onto the object.

This design creates a highly diffuse bright field that ensures particularly homogeneous illumination. The camera “sees” through the half-mirror without being “blinded” by reflections or mirroring.

Comparison of illumination based on the example of cable inspection

Machine vision inspection places high demands on illumination, as the image material generated must be able to make even small defects visible. This poses two significant challenges:

On the one hand, defects have to be visualized on different surfaces, e.g. on rough or curved surfaces. Especially here, a high contrast and consistent illumination of the test object is particularly necessary in order to visualize three-dimensional defects such as cracks, scratches, dents or bubbles.

Cable surface illuminated with ring light

Cable surface coaxial illuminated

On the other hand, image recognition must be able to manage very high production speeds. This requires high frame rates and short exposure times. To ensure that the automatic image evaluation functions reliably, a particularly high light output is required.

But even in static shooting situations, a steady quality and quantity of light are a major advantage.

That’s why we rely on up to 128 high-performance LEDs with a light output of up to 48 watts and a high color rendering of Ra 95.