nWood Solution

Optical Inspection of Tree Logs

nWood Tree Log Inspection

The Wahtari tree log inspection solution nWood can analyze various parameters and quality characteristics directly in your production line simultaneously. In case of any deviation, certain signals can be send out (e.g. sorting log out) and operational parameters can be documented.

The system exceeds the visual control of a worker both in precision and efficiency as it inspects under industrial conditions, during ongoing production and around the clock. It is easy to use, Plug & Play and allows convenient one-man operation. Both analysis and evaluation are performed on-the-edge without cloud or Internet connection. This enables highest speed, maximum data security and lowest latencies.

nWood is available in different versions and can be adapted to your individual requirements.

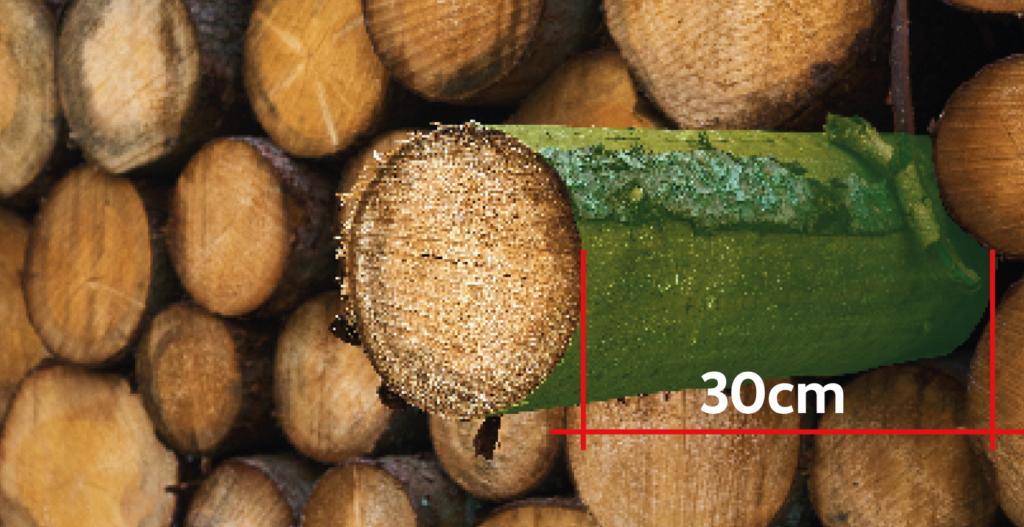

Bark Detection

Areas of application

Artificial Intelligence as the Heart for the Automated Inspection of Tree Logs

Inspect Degree of Debarking

automatic classification into levels of debarking

Quality Classification

automated sorting out of unwanted wood characteristics, e.g. branchiness, bending, tapering, spiral growth, wood rot

Length Measurement

length estimation or

assignment to groups

Volume Measurement

volume estimation or

assignment to groups

Diameter Control

diameter estimation or assignment to groups

Advantages of the nWood Inspection

High Precision

clear identification even in difficult situations

Extreme Performant

recording and evaluation in real time

Easy Adjustment

adjustable to new product features

Edge Computing

no connection to a data center due to onboard detection

Seamless Integration

easy integration into your system (PLC)

Consistent Quality Inspection

thanks to consistently working system

Technical Highlights

Teach & Go

short training phase

Low Maintenance

no tools necessary

Production Speed

up to 120m/min belt speed

Rentable

short ROI

Adaptable LED Lighting

LED or IR

24/7 Continuous Operation

> 99,5% availability

IP67 Protected Camera Housing

measurement of wet media/ easy cleaning

Process Reliable

insensitive to industrial influences, e.g. waterdrops or dust particles

100% Control

for highest quality requirements

Few System Components

Functionality of the nWood Solution Based on the Example of Debarking

Problem

For further processing, the bark of logs must be removed since bark does not consist of the same fibrous material typical for wood. Process-related, the bark is not removed completely when passing through the decortication drum for the first time. Therefore, most logs need to undergo a second, visual inspection by a worker subsequent to the first decortation process.

This labor-intensive and physically demanding process, in which employees have to remove only partial decorticated logs manually, can be automated by the intelligent camera system by Wahtari.

Easy Integration Into Existing System Concept

The smart camera can be installed on existing infrastructure, own masts or walls thanks to its integrated mounting bracket. Once installed, the camera needs to be adjusted, e.g. for viewing angle, zoom and focus.

The uncomplicated commissioning requires only little technical Know-how. Numerous interfaces and industrial standards, such as OPC UA, Profibus and Profinet, allow an easy integration into existing system concepts while ensuring the lowest possible latencies. Signals, e.g. for the control of locks, can be send directly via an analog signal.

Strong Hardware Platform

Industrial IO

nWood Solution by Wahtari

Wahtari’s AI-based camera system offers a fully automated, complete solution for optical inspection. With a detection accuracy of over 98%, Wahtari nWood reliably identifies even small bark remnants during operation and sends signals to your system control in real time. A controllable lock diverts defective logs to another pass through the debarking drum.

The intelligent camera is suitable for indoor and outdoor operation and can withstand temperatures between -20° and +50° Celsius. At belt speed up to 200m/min, nWood records parameters such as debarking degree, size, contours, length and diameter of logs and piles simultaneously. Individual logs can be distinguished. Weather-related wood discoloration does not affect the detection.

The technology is based on deep neural networks, which are trained project-specifically for the recognition of the residual bark content by using image recordings of the processed logs. Once the desired recognition rate is achieved, no further training is required.

The artificial intelligence runs “on-the-edge” on site without internet or cloud connection – for the highest speeds, lowest latencies and greatest possible data security.

nWood in Your Company